Choosing the right cable is not as simple as picking the first one you see in a catalog. The wrong cable can result in equipment failure, power loss, safety hazards, or project delays. To avoid these issues, businesses must carefully evaluate the technical requirements, environment, and compliance standards.

Here’s a step-by-step guide from Neskeb to help you select the right cable for your project.

1. Identify the Application

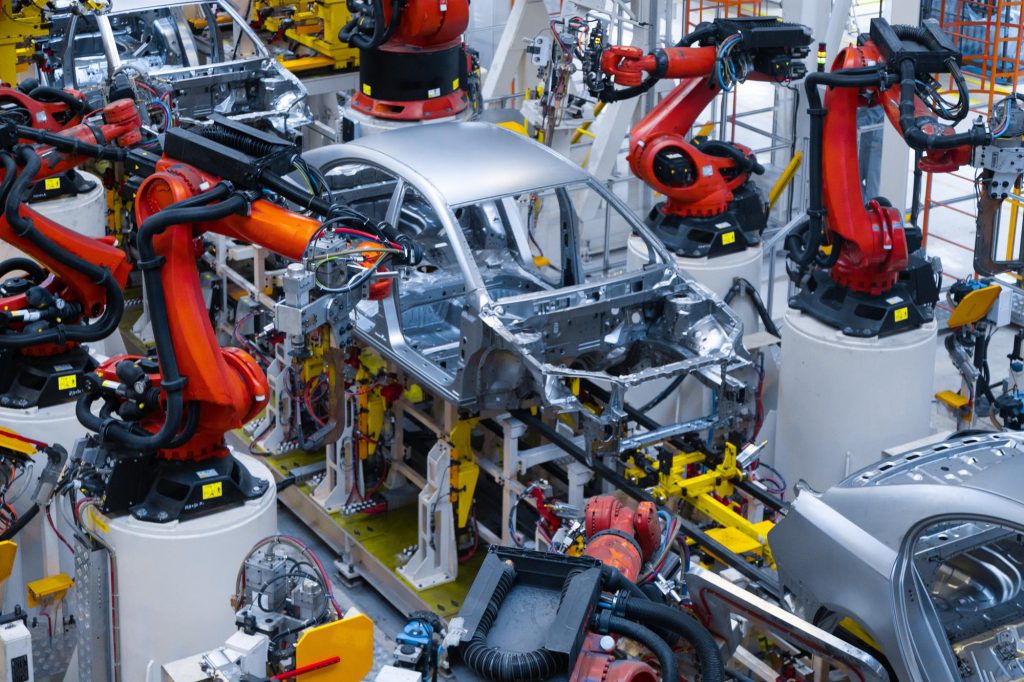

- Power Transmission – Requires high-voltage or medium-voltage cables.

- Automation/Control – Needs control or instrumentation cables.

- Data & Networking – Fiber optic or Ethernet cables are best.

The first step is always understanding where and how the cable will be used.

2. Check Voltage & Current Ratings

Each cable has a specific voltage rating (e.g., 110V, 220V, 11kV) and current capacity. Using an underrated cable may cause overheating, while an overrated cable increases unnecessary costs.

✅ Always match the cable rating to your equipment’s requirements.

3. Consider Environmental Conditions

Cables often face harsh conditions. Ask yourself:

- Will the cable be installed indoors or outdoors?

- Will it be exposed to chemicals, heat, or moisture?

- Does it need to be fire-resistant or UV-protected?

For example:

- Outdoor power lines → UV and weather-resistant cables.

- Factories with high heat → Heat-resistant cables.

- Oil plants → Chemical-resistant sheathing.

4. Ensure Compliance with Standards

Using certified cables is not just about quality—it’s also about legal compliance. Look for:

- IEC, ISO, BIS certifications.

- Fire and safety approvals.

- Environmental certifications.

At Neskeb, every cable undergoes rigorous testing and certification before reaching clients.

5. Factor in Cost vs. Longevity

It’s tempting to choose cheaper cables, but they often need frequent replacements. A higher-quality cable may cost more upfront but saves significantly in the long run by reducing downtime, energy loss, and maintenance costs.

Conclusion

The right cable ensures safety, efficiency, and smooth operations. By considering application, rating, environment, compliance, and cost, you can make an informed decision.

At Neskeb, we don’t just manufacture cables—we help our clients choose the right ones for their unique needs.